Mentsen’s Custom Tinplate Packaging Solutions

Where Efficiency Meets Expertise: Your Goods, Our Responsibility.

Custom Tinplate Packaging Manufacturer

We specialize in delivering premium tinplate packaging solutions tailored to meet the unique demands of your business. Our offerings include a broad range of customizable containers, jars, and lids designed for diverse industries, from food and beverages to cosmetics and gift packaging.

Food & Beverage Tinplate Packaging

Our tinplate containers for food and beverages are designed to meet the highest safety and quality standards. From airtight solutions for dry goods to custom designs for branding, our packaging ensures product freshness and a premium appearance. Ideal for snacks, powdered drinks, or condiments, we prioritize functionality and visual appeal.

Cosmetics Tinplate Packaging

Make your brand stand out with beautifully crafted tin containers for cosmetics. Designed for durability and elegance, these tins are perfect for creams, balms, or powder-based products. Their premium finishes, customizable designs, and compact portability create a luxurious user experience while safeguarding product integrity.

Pharmaceutical Tinplate Packaging

When safety and compliance are paramount, our pharmaceutical tinplate containers provide a trusted solution. Designed for pills, powders, and ointments, these containers offer tamper-evident options and precise seals to protect sensitive products.

Tea and Coffee Tinplate Packaging

Enhance the appeal of your tea or coffee with durable and attractive tin containers. These tins are designed to preserve aroma and freshness while providing a canvas for distinctive branding. Whether for loose leaves, ground coffee, or pods, our packaging solutions cater to a variety of preferences and uses.

Candle Tinplate Packaging

For candle makers looking to combine style and practicality, our tins are an ideal choice. With heat-resistant materials and customizable finishes, these containers provide a sleek, reusable packaging solution. Their portability and safety features make them perfect for candles of all types, including scented and travel-friendly designs.

Gift Tinplate Packaging

Our tinplate packaging adds a touch of sophistication to any gift product. Whether for seasonal promotions, limited editions, or corporate giveaways, these containers offer versatile designs and premium finishes that make a lasting impression.

Tailored Tinplate Packaging Solutions for Your Business

As a professional tinplate packaging manufacturer, our custom services include:

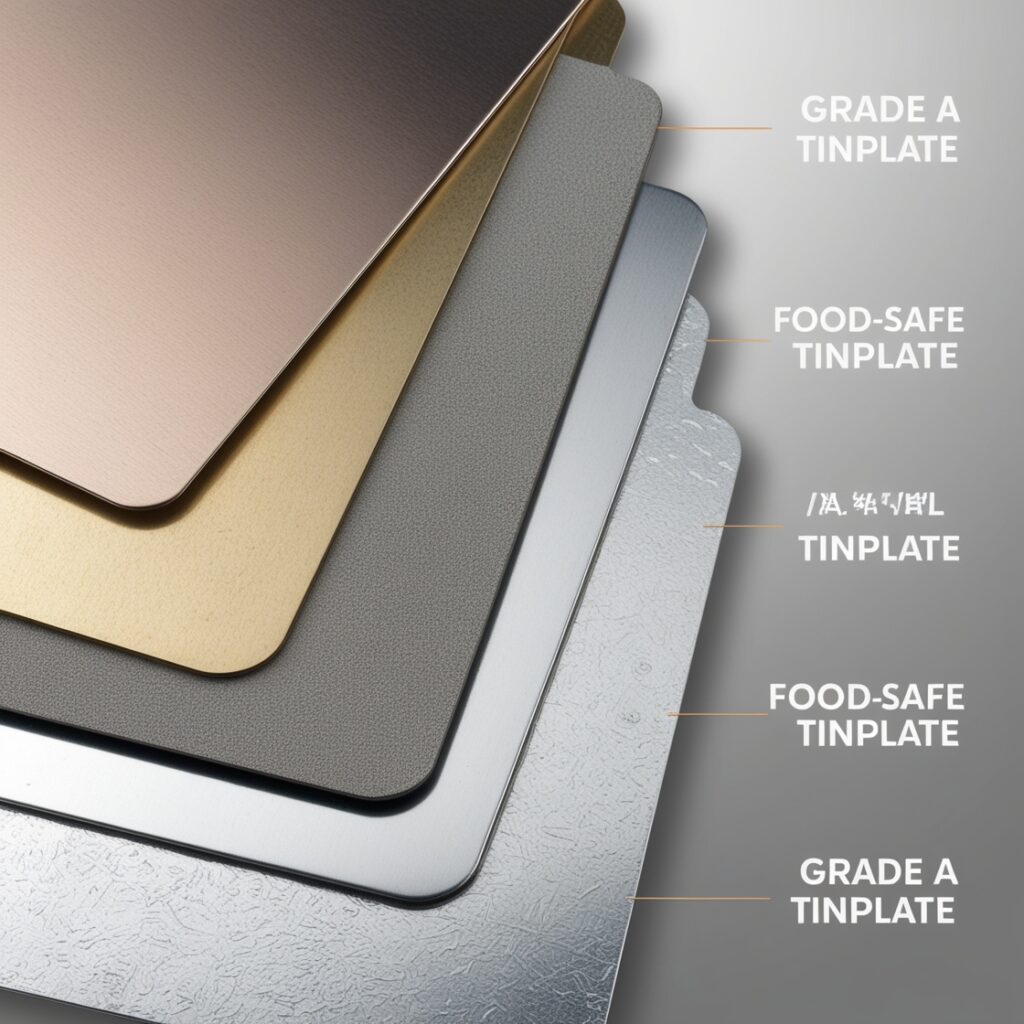

- Material Selection: Choose from a variety of high-quality tinplate options, each suited for different industries and product types.

- Design Support: Work with our in-house design team, skilled in custom artwork, 3D mock-ups, and prototype creation.

- Size and Shape Customization: Whether you need small jars or large containers, we provide packaging in the exact size and shape you require.

- Decoration Options: Select from a range of printing techniques, including screen printing, embossing, and labeling, to enhance your brand’s appeal.

- Finishing Touches: Choose from a variety of finishes, such as matte, glossy, or metallic, to add the perfect touch to your packaging.

Let’s collaborate to create packaging that elevates your brand with precision and quality.

Your Ultimate Tinplate Packaging Solution Provider

We’re more than just a tinplate container manufacturer. Our product range includes custom-designed containers, jars, tins, and closures for a variety of industries. We’re committed to delivering your orders on time, adhering to international quality standards, and crafting tailored packaging solutions that fit your unique needs.

Not sure which tinplate material is best for your packaging? We’ll help you select the ideal grade to suit your application’s requirements.

Need assistance with design or prototyping? Our experienced team offers everything from custom artwork to full-scale 3D mock-ups.

From small batches to large production runs, we can handle it all. Our flexible production plans to support your business grow.

We guarantee high-quality, precise manufacturing with multiple finishing options like printing, embossing, and coating to enhance your product’s look.

Why Choose Mentsen for Your Tinplate Packaging Needs?

We are committed to providing high-quality, custom tinplate packaging solutions that enhance your brand and meet your unique needs. With years of experience, we offer unmatched expertise and dedicated service, ensuring every packaging project is executed with precision and care.

Flexible Order Quantities

Whether you need a small custom design or a large-scale order, Mentsen accommodates orders of any size, from small batches to large production runs.

Expert Craftsmanship

With years of experience in the tinplate packaging industry, our skilled team ensures high-quality production that meets your exact specifications.

Competitive Pricing

We offer the best of both worlds—superior packaging solutions at competitive prices, delivering premium value without exceeding your budget.

Comprehensive Packaging Solutions

Mentsen offers a complete range of tinplate packaging options, providing everything from design to production, all while meeting global standards.

Reliable Delivery Times

Our streamlined production process and commitment to efficiency ensure your orders are delivered on time, every time.

Customer Service Guarantee

We focus on building long-term relationships with our clients, offering seamless communication and making the entire packaging process simple and reliable.

Your Complete Guide to Sourcing Tinplate Packaging Solutions

Tinplate packaging is widely used across industries such as food and beverage, cosmetics, pharmaceuticals, and gift packaging.

Whether you’re looking to import custom tinplate containers for your products or exploring bulk procurement for your business, this guide is designed to provide you with all the key information you need to make informed decisions.

Table of Contents

What is Tinplate Packaging?

Tinplate refers to steel sheets that are coated with a thin layer of tin. This material is widely used for packaging products that require a strong, durable, and corrosion-resistant container. Tinplate packaging solutions are commonly used for food cans, beverage containers, and cosmetic jars due to their ability to preserve the contents, protect against contamination, and offer excellent printing and design options.

Tinplate is chosen for its strength, resistance to rust, and ability to withstand high temperatures, making it ideal for a range of applications. Moreover, it is fully recyclable, which adds to its environmental appeal, especially in industries that prioritize sustainability.

The Benefits of Tinplate Packaging

Durability: Tinplate containers are robust and capable of withstanding significant pressure during transportation and storage. This makes them ideal for heavy-duty applications.

Corrosion Resistance: The thin layer of tin protects the underlying steel from corrosion, making tinplate suitable for products that may be exposed to moisture or harsh conditions.

Tamper-Proof: Tinplate containers offer a higher level of security than plastic or glass packaging, as they are difficult to tamper with, providing extra assurance for both manufacturers and consumers.

Branding Opportunities: Tinplate offers excellent surface printability. Brands can create eye-catching designs, which makes it a popular choice for products that require attractive packaging.

Environmental Sustainability: Tinplate is highly recyclable. Many manufacturers are now emphasizing eco-friendly solutions, and tinplate can be recycled endlessly without losing quality, reducing waste in landfills.

How to Find the Right Tinplate Packaging Supplier

Sourcing the right supplier for tinplate packaging is essential for ensuring that you get high-quality products at competitive prices. The process of finding and selecting a reliable supplier involves several important steps:

1. Understand Your Product Needs

Before you start looking for a supplier, clearly define your packaging requirements. Consider the following factors:

- Size and shape: Do you need standard cans, custom jars, or specialized shapes?

- Material requirements: Ensure the tinplate is suitable for your product type, especially if you need food-grade or pharmaceutical-grade materials.

- Design: Think about whether you need custom designs, specific print capabilities, or a unique finish (e.g., matte, gloss, embossed).

- Quantity: Will you need bulk orders, or are you looking for small batch runs?

2. Research Potential Suppliers

There are many suppliers of tinplate packaging around the world, particularly in China, which is a major hub for manufacturing. When conducting research, look for:

- Supplier experience: Choose suppliers with a proven track record of producing high-quality tinplate packaging. Look for manufacturers that specialize in your industry (e.g., food, cosmetics).

- Reputation: Check reviews, testimonials, and references from other clients to ensure the supplier is trustworthy and reliable.

- Certifications: Verify that the supplier holds relevant certifications, such as ISO 9001 for quality management or FDA approval for food-grade materials.

3. Evaluate Supplier Capabilities

Not all suppliers are equal when it comes to product quality, delivery times, and customer service. You should assess:

- Production capacity: Can the supplier meet your volume needs? Do they have the facilities and workforce to handle large or complex orders?

- Quality control procedures: Make sure the supplier has robust quality control mechanisms in place. This may include testing raw materials, performing regular inspections during production, and conducting final product checks.

- Lead times: Understand the supplier’s typical lead times for production and shipping, particularly if you are working on tight deadlines.

- Customization options: If your packaging needs require specific customization (such as unique sizes, shapes, or finishes), ensure the supplier has the capability to deliver.

4. Request Samples

Before committing to a bulk order, request product samples to inspect the quality. Check for:

- Material quality: Ensure the tinplate is smooth, corrosion-resistant, and meets your durability requirements.

- Printing and design: Evaluate the quality of the printed design and finish. Ensure that colors, logos, and text are clear and sharp.

- Functionality: If applicable, check that the packaging is easy to open, reseal, and store.

Quality Standards and Certifications for Tinplate Packaging

The quality of tinplate packaging is paramount, especially for products that involve food, beverages, or pharmaceuticals. Adhering to international quality standards and certifications ensures that the packaging is safe, effective, and compliant with regulations.

1. ISO Certifications

ISO 9001 is the most common quality management certification. Suppliers that hold this certification demonstrate a commitment to producing high-quality products consistently. You should also inquire about other certifications specific to your product industry, such as:

- ISO 22000 (for food safety management)

- ISO 13485 (for medical device packaging)

- BRCGS Packaging Materials (for food packaging)

2. FDA Approval for Food Contact Materials

If you are sourcing tinplate packaging for food or beverage products, make sure that the supplier’s tinplate is FDA-approved for food contact. This certification ensures that the materials used in packaging are safe for storing consumables.

3. RoHS Compliance

For products in certain industries, it is essential to ensure that the tinplate packaging is RoHS-compliant (Restriction of Hazardous Substances). This ensures that harmful substances, such as lead or mercury, are not present in the packaging materials.

Customization and Design Options for Tinplate Packaging

Tinplate packaging offers a wide range of customization and design options, making it a popular choice for brands that want to stand out. These options include:

Shape and Size: Custom shapes and sizes can be created based on the specific needs of your product. Tinplate containers are available in various standard shapes (round, square, rectangular), but manufacturers can also create unique, tailor-made shapes for a distinctive look.

Surface Finishes: Tinplate packaging can be finished with different coatings, including glossy, matte, or embossed finishes. The surface finish can significantly affect the appearance of the packaging and is essential for branding.

Printing: High-quality printing is one of the key advantages of tinplate packaging. You can choose from techniques such as:

- Offset printing: Ideal for high-quality, multi-color graphics.

- Screen printing: Suitable for large areas and simple designs.

- Embossing/Debossing: Adds texture and a premium feel to the packaging.

Lidding and Closures: Tinplate packaging often includes specific closures such as twist-off lids, press-on caps, or pull-tabs, which help improve functionality and convenience.

Controlling Costs and Negotiating with Suppliers

Controlling costs while sourcing tinplate packaging can be challenging, especially as global prices fluctuate. Here are a few tips for managing costs effectively:

Bulk Purchasing: Ordering in bulk typically results in a lower per-unit price. If possible, consider long-term contracts or larger orders to secure discounts.

Negotiate Terms: Don’t hesitate to negotiate on price, especially if you’re ordering large volumes. Be prepared to discuss factors such as payment terms, delivery schedules, and discounts for repeat orders.

Compare Multiple Suppliers: Get quotes from multiple suppliers to ensure you’re getting the best price and quality for your needs.

Shipping and Logistics for Tinplate Packaging

Shipping tinplate packaging can be complex due to the weight and size of the containers, as well as the need for protection against damage during transit. To ensure smooth logistics:

Shipping Methods: The most common shipping methods for tinplate packaging are ocean freight for bulk orders or air freight for smaller shipments. Choose the method that balances cost and speed.

Packaging for Transport: Ensure the tinplate packaging is securely packed to avoid damage during transit. Proper cushioning and reinforcement are essential, especially if the packaging has intricate designs or coatings that could be scratched.

Customs and Duties: Be aware of customs regulations and duties that apply when importing tinplate packaging. Make sure you understand the customs process in both your home country and the supplier’s country.

Conclusion

Sourcing tinplate packaging solutions requires careful consideration of material properties, supplier capabilities, quality standards, and customization options. By following the steps outlined in this guide, you can successfully navigate the sourcing process and secure high-quality packaging that meets both your functional and aesthetic needs. Remember to prioritize quality control, cost management, and sustainability in your purchasing decisions to ensure long-term success in your packaging endeavors.

Get in touch with our agent

Your message will be responded to within 24 hours.

We promise not to send you any spam messages